4 grade

4.1 qualified products

4 1.1 should be consistent with the requirements of GB/T 6087.

4 1.2 product in accordance with GB/T 6087, torque test retest precision should be qualified.

4 1.3 product exposed polishing surface roughness Ra value less than 2.5μ M.

4 1.4 main parts of the heat treatment parts of the key technical indicators (of hardness and metallographic ) pass rate of more than 90%.

4 1.5 main parts and main project checks passing rate of less than 85%. The main parts and the main project ( see Appendix B tip attached

Book ).

4 1.6 product taper should be consistent with the provisions of GB/T 6090, the inspection and assessment see Appendix A ( standard ).

4 1.7 enterprises to deal with the views of users processing time, processing results archive, and recurrent stage quality analysis report. User reaction

Mapping application, reliable.

4.2 grade

4 2.1 geometric accuracy should be 20% accurate storage.

4 2.2 product outer surface not to bump, scratch, such as corrosion damage.

4 2.3 main parts of the heat treatment parts of the key technical indicators qualified rate of more than 95%.

4 2.4 main parts and main project checks pass rate of less than 90%.

4 2.5 taper contact rate of not less than 75%.

4 2.6 users reflect the good.

4 2.7 of the remaining shall comply with the requirements of 4.1.

4.3 excellence in goods

4 3.1 geometric accuracy should be 30% accurate storage.

4 3.2 output torque increased standard torque 20%.

4 2.3 main parts and main project checks pass rate of less than 95%.

4 2.4 taper contact rate of not less than 80%.

4 2.5 users reflect the good.

4 2.6 of the remaining shall comply with the requirements of 4.2.

Spanner drill chuck tapers surface coloring inspection and evaluation

A1 coatings

The red lead paint mixing as medium, is also allowed in without dispute cases using red ink, special pencil painting medium.

Red lead paint mixture consists of red lead, machine oil and kerosene lamps and compounding, the weight ratio:

Red lead, machine oil, kerosene lamps = 100∶ 7∶ 3

Red lead, machine oil and kerosene lamp quality indicators with reference to the provisions of JB/T 5563.

A2 test method

Wipe the gauge to be detected and the conical surface, the coating in the plug cone surface at a distance of 120 degrees: bus three, coated with a width of about 5

Mm painted lines, coating uniformity, thickness of less than 4μ M. Gauge and test conical combination, applying appropriate axial force so that the lapping surface tension

Close contact, relative rotation of less than 60 degree angle, then return to original position off.

A3 evaluation

Observation of the color line. After the contact condition of the color line, to the real contact length average with the lapping surface working length ratio that contact

Rate of assessment, exposure rate general to the percentage from the tapered end said, in the contact rate range of 75% should not have obvious gap area.

The real contact length is defined by a painted line continuous contact length or the intermittent contact length and.

A4 coating thickness limit easy judgement method

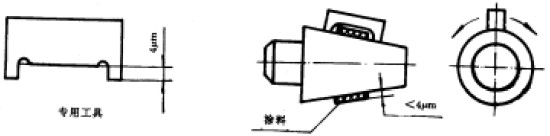

Coating thickness limit simple judgement method of figure A1.

Special tool in the coating cone along the circumferential direction moving slowly, the groove will not rub coating is the coating thickness is less than 4 μm limit

Value.